Book Appointment Now

Bottle Blowing Machine

Newpeak bottle blowing machines deliver high-efficiency PET bottle production with advanced blow moulding technology. Reliable, fully automatic, and ideal for all beverage industries.

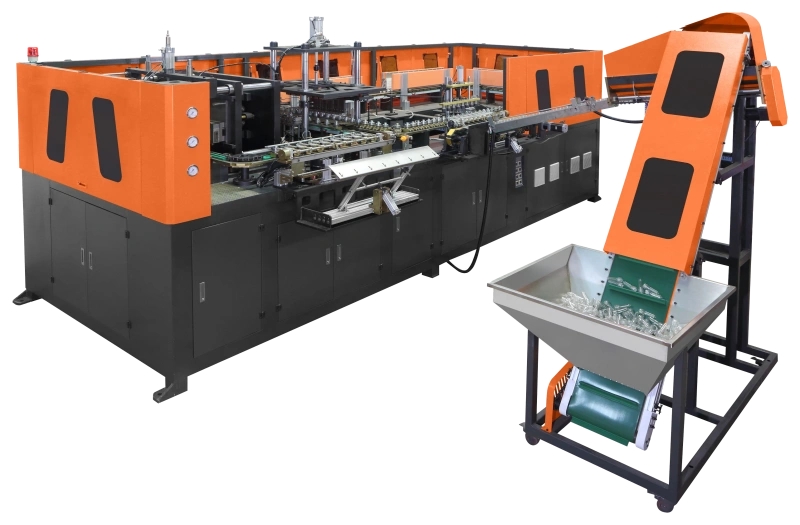

PET Bottle Automatic Blowing Machine

Newpeak’s bottle blowing machines are high-performance, fully automatic plastic bottle manufacturing machines designed for PET bottles ranging from 0.5L to 2L. Built on over 15 years of experience in the bottle blowing machine market, our machines deliver stable performance, high efficiency, and consistent quality for breweries, beverage producers, and plastic bottle production machine users worldwide.

Whether you need a plastic PET bottle making machine, a water bottle manufacturing machine, or an automatic bottle making machine, Newpeak provides solutions that cover all types of PET, recycled PET (rPET), and refillable PET (refPET).

Key Features of Newpeak Bottle Blowing Machines

Fully automatic blow and blow moulding technology for uniform bottles

Two-step plastic blow moulding process with high precision and low rejection rates (<0.2%).

Multiple cavity options (2–6 cavities) for high production efficiency and faster PET bottle output.

Advanced PLC for stable operation and bottle blower control.

Adjustable pre-heating voltage control for optimal bottle formation.

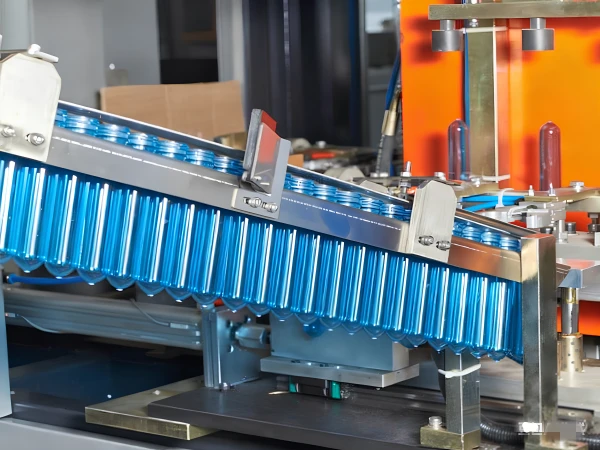

Automatic preform conveyor and self-rotation with infrared pre-heater ensures even heat distribution.

Safety devices with automatic locking for a secure production environment.

FESTO air cylinder to reduce contamination and noise.

Independent air pressure design for blowing and mechanical actions.

Strong clamping force with double crank links for reliable mould locking.

Dual operation modes: automatic or manual for flexible and efficient production control.

Low cost, easy maintenance, high efficiency, and excellent cooling system.

Technical Specifications

| Parameter | Specification | Parameter | Specification |

|---|---|---|---|

| Product Name | Bottle Blowing Machine | Material | PET, rPET, refPET |

| Item Type | Plastic Bottle Making Machine | Certification | CE, SGS, ISO |

| Model | XF-A4 | Warranty | 1 year |

| Productivity | 3200–4000 bottles/hour (depends on bottle design) | Machine Size | 1908×1858×1920mm |

| Bottle Volume | 0.5L–2L | Weight | 3600kg |

| Bottle Diameter | 20–100mm | Air Source | LP: 1.6 m³/min 1.0MPa, HP: 1.0 m³/min 3.0MPa ×2 sets, Air Dryer: 15L/min |

| Bottle Height | 50–350mm | Cooling Water | 2.0 m³/min 3.0MPa ×1 set |

| Neck Diameter | 15–38mm | Preform Unscrambler | 2000×950×2480mm, 250kg |

| Mold | 4 cavities, 240mm thickness, 500×500mm size | Main Machine Power | 49 kW |

| Electrical Source | 380V 3Phase / 220V 3Phase 50/60Hz |

Advantages of Newpeak Bottle Blowing Machines

Fully Automatic PET Bottle Blowing Machine

Reliable bottle blow moulding and blow method technology.

Customizable for various PET bottle shapes and sizes.

Cost-effective compared to other bottle blowing machine manufacturers.

Ideal for small to large-scale production, including plastic bottle maker and bottle machine maker setups.

Supports both bottle blow moulding and blow and blow moulding processes.

Fully automatic process ensures low labor costs, high yield, and product consistency.

Applications

Water, juice, and beverage plastic bottle production machines.

Breweries and beverage companies requiring reliable PET bottles.

Food and beverage industries seeking machine for plastic bottle with high efficiency.

Newpeak’s bottle blowing machines China solutions combine advanced plastic blow moulding process technology with flexibility, precision, and environmental benefits. From plastic bottle maker to automatic bottle making machine, our bottle blowing machines are engineered to deliver the best performance in the bottle blowing machine market.

Get a Quote for Your Water Bottling Project