Book Appointment Now

Other Auxiliary Equipment

If you are in need of high-quality, professional and friendly dental care, look no further than our clinic.

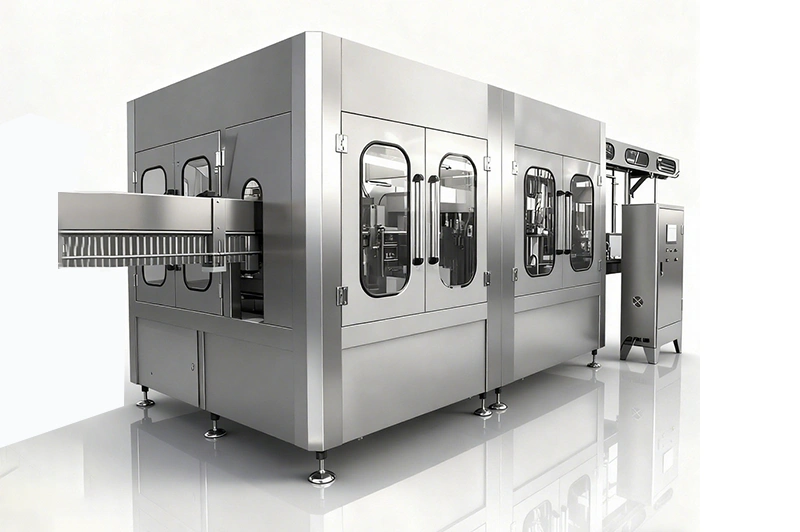

Auxiliary Equipment for Bottle Filling Lines | Efficient, Precise, and Comprehensive Solutions

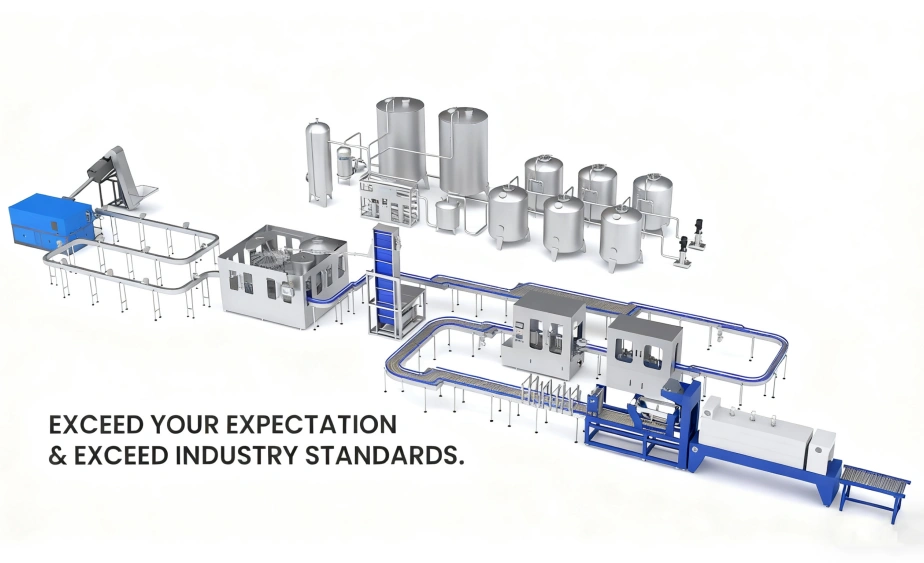

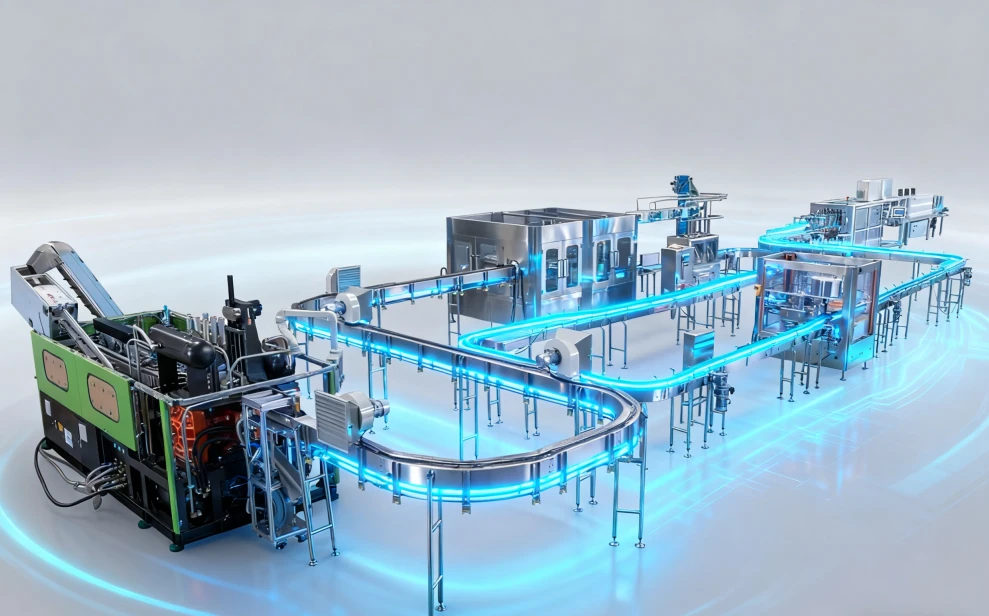

In a complete bottle filling production line, auxiliary equipment is equally crucial. Newpeak provides a full range of auxiliary solutions, covering every stage from water treatment, bottle handling, and conveying systems to packaging and quality inspection, ensuring your production line operates efficiently, reliably, and hygienically.

Complete Range of Auxiliary Equipment

Water Treatment Systems

We offer efficient RO (Reverse Osmosis) systems, ultrafiltration systems, and UV sterilization units to ensure water purity, meet food safety standards, and provide a stable water source for your filling line.

Bottle Handling Equipment

Including bottle blowing machines, bottle washers, and bottle dryers, these devices enable automated cleaning and drying, reducing contamination risk and improving production efficiency.

Packaging and Labeling Equipment

Our range covers capping machines, automatic labeling machines, shrink film packaging machines, and case packers, delivering accurate placement, consistent packaging, and reduced labor costs.

Conveying and Buffer Systems

We provide automatic conveyors, buffer tables, and rotary tables to ensure smooth bottle transport, flexible line layout, and minimized downtime for continuous production.

Liquid Handling and Filling Auxiliary Equipment

Including pumps, blending tanks, mixers, and metering systems, designed for various liquids such as water, juice, carbonated drinks, dairy, and sauces, achieving high-precision filling and stable flow control.

Inspection and Control Systems

Equipped with metal detectors, liquid level sensors, PLC control systems, and touchscreen interfaces, these systems monitor production processes in real-time, ensuring product safety while offering easy and intelligent operation.

High-Precision Labeling Machine Solutions

A reliable Labeling Machine is essential as the final step of any liquid packaging line. Whether you are labeling round, square, flat, or curved bottles, our systems ensure perfect application even when bottles are wet after filling. Ideal for food, beverage, pharmaceutical, chemical, and personal care products, our automatic labelers are designed for both speed and precision.

We offer multiple configurations:

Wrap-around labeling for cylindrical bottles

Front, back, and neck labelers for wine, spirits, or specialty beverages

Shrink sleeve labeling systems for a 360° brand presentation

Thanks to ergonomic design, fast format changeovers, and tool-free adjustments, our machines minimize downtime and keep your production line running efficiently.

Automated Bottle Packing Machine

After filling, capping, and labeling, the Bottle Packing Machine completes your packaging process. We provide end-of-line systems that bundle, carton, or palletize products efficiently for secure storage and retail-ready displays.

Packaging Options Include:

PE film wrapping for bottles, cans, Tetra Pak cartons, and aluminum containers

Carton packaging systems with hygienic, easy-clean designs

Configurations such as 4×6, 3×4, and 2×3 packs

Speeds ranging from 10–50 packs per minute, adaptable to container size

Ideal for plastic, glass, aluminum bottles, and beverage cans

Product Advantages

High Efficiency: Automated operation reduces labor and increases output

High Precision: Advanced metering and filling control ensures consistent quality

Hygienic and Safe: Fully enclosed design with food-grade materials meets hygiene standards

Flexible Compatibility: Suitable for various bottle types, sizes, and liquid products

Easy Maintenance: Modular design allows convenient upkeep and parts replacement

Services and Support

Custom Solutions: Tailored equipment packages for full or partial filling lines

Installation and Commissioning: Professional on-site setup ensures smooth operation

Training and Guidance: Operator training and maintenance instructions for quick mastery

Long-Term Support: Spare parts supply, technical support, and remote troubleshooting

Spare Parts of Filling Line & Technical Support

To ensure your filling line operates at peak efficiency, we offer a comprehensive range of spare parts for all types of filling lines.

Our inventory includes filling valves, capping heads, conveyor components, labeling machine parts, and control system modules, covering every critical component of your production line.

By maintaining ample stock, we can provide fast delivery and immediate replacement, minimizing downtime and keeping your operations running smoothly and without interruption.

Trusted by Customers

Newpeak’s auxiliary equipment is widely used in bottled water, juice, carbonated drinks, and dairy production lines, earning high praise for reliability, cost-effectiveness, and dependable after-sales service.

Why Work with Us

Turnkey Integration: From Labeling Machine to Bottle Packing Machine, Injection Moulding Machine, and Bag Filling Machine, we provide end-to-end solutions.

Custom Engineering: Each system can be tailored to your bottle type, label format, or packaging material.

Reliable After-Sales: Fast spare parts supply and remote technical support guarantee long-term stability.

Get a Quote for Your Water Bottling Project